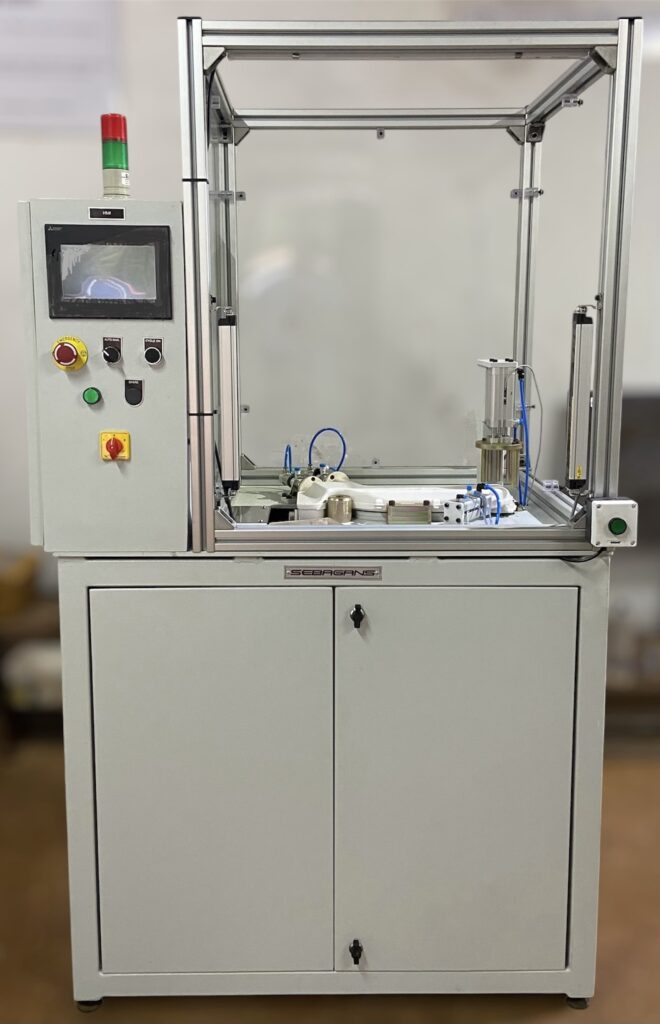

AIR PRESSURE DROP TESTING MACHINE

Features :

- Auto Sealing System for consistent and leak-free clamping of components

- Auto Air Inlet with solenoid-controlled filling cycle

- Digital Pressure Control for precise and repeatable test pressure setting

- Adjustable Inlet Pressure to suit different components and test standards

- Adjustable Test Timing (fill time, stabilization time, and test duration)

- High-Accuracy Pressure Sensor for reliable leak detection

- Safety Curtains for enhanced operator protection during testing

- PLC-Based Control System with user-friendly HMI

- Pass / Fail Indication with visual and audible alerts

- Recipe Management for storing multiple test parameters

- Data Logging Option for quality tracking and traceability

- Compact & Robust Construction suitable for shop-floor use

- Low Air Consumption with optimized pneumatic design

- Maintenance-Friendly Design for easy servicing

Applications :

- Home appliances and white goods

- Automotive and auto-ancillary components

- Pneumatic and hydraulic fittings

- Valves, pipes, hoses and assemblies

- Packaging containers and sealed components

The Air Pressure Drop Testing Machine provides fast, clean, and reliable leak detection with high accuracy and repeatability. Automated controls reduce human error, improve productivity, lower operating costs, and ensure safe, continuous operation on the shop floor or in automated lines.